In the ideal world all bulk fertilisers should be stored in properly constructed bays in closed sheds. But such sheds and the equipment are not always available. Instead, many grain growers use silos and belt conveyors or augers to store and handle bulk fertiliser on farm. HOWEVER only certain fertilisers can be stored in silos, and only short periods of time.

Handling equipment – Ideally, bulk fertiliser should be moved with a belt conveyor, rather than a screw auger to maintain granule integrity and avoid generation of dust and fines. To assist material handling it is recommended that the base cone of fertiliser silos be at least 45° steep. Also avoid excessive handling as it can reduce the effectiveness of any fertiliser coating agents and oils used on some fertilisers to help prevent moisture absorption.

Many factors influence how well and for how long a fertiliser will store in a silo. One of these is Fertiliser salts are sensitive to the humidity of the surrounding air; above certain relative humidities, they will absorb water. A fertiliser product’s Critical Relative Humidity (CRH), is the relative humidity above which the fertiliser readily absorbs moisture from the atmosphere. Fertilisers with a CRH greater than 70% generally have good storage characteristics and those with a low CRH don’t store well. The CRH of fertiliser blends is usually no better than that of the ingredient with the lowest CRH, and is often depressed below this figure

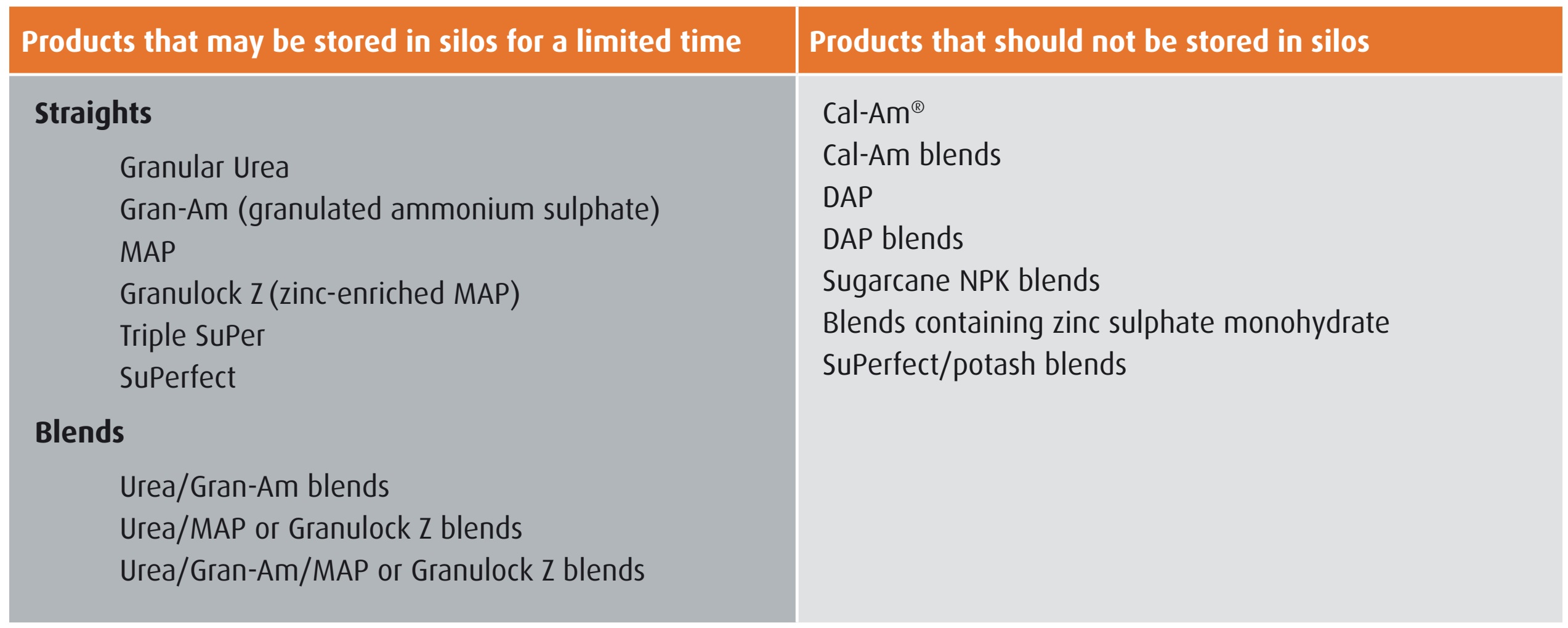

The following table shows a guideline for silo storage some IPF Fertiliser products. Please note that the storage of suitable fertilisers in silos should be only be for short periods or avoided. If in doubt please contact us for advice.

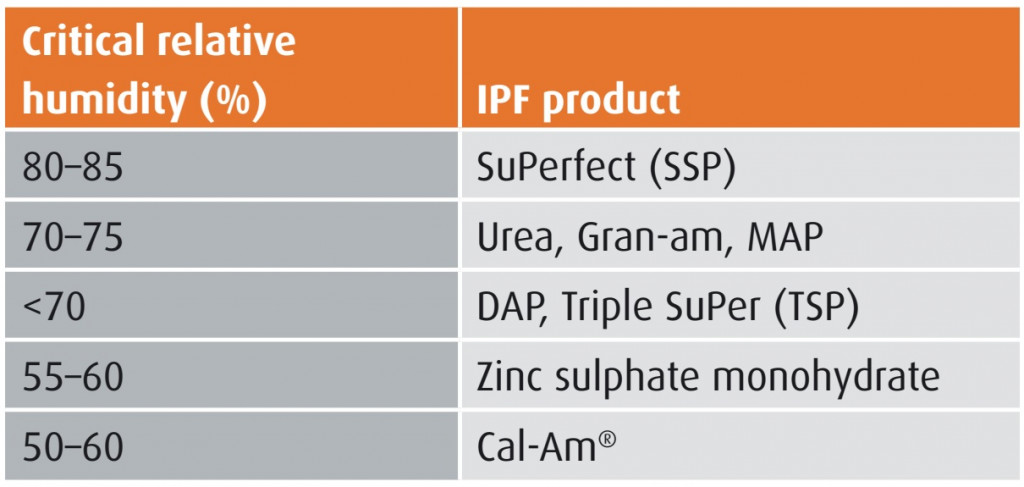

The following table shows a guideline for Critical Relative Humidity (CRH) of IPF Fertiliser products.